Understanding What is an ECM Fuse

When it comes to automotive engineering, the smallest components often have the largest impact. ECM fuses, while seemingly insignificant, play a crucial role in vehicle performance and efficiency. Understanding their function can greatly enhance your ability to maintain and troubleshoot your vehicle.

The Engine Control Module (ECM) is at the heart of modern vehicles, managing everything from fuel injection to emissions control. Without properly functioning ECM fuses, these vital communication lines can break down, leading to a host of performance issues. Recognizing how these fuses operate is essential for any vehicle owner or enthusiast.

Let’s explore the critical role of ECM fuses, their impact on engine performance, common symptoms of failure, and effective diagnostic measures. Knowing what to look for and how to maintain these essential components can help ensure your vehicle runs smoothly and efficiently.

What is an ECM Fuse?

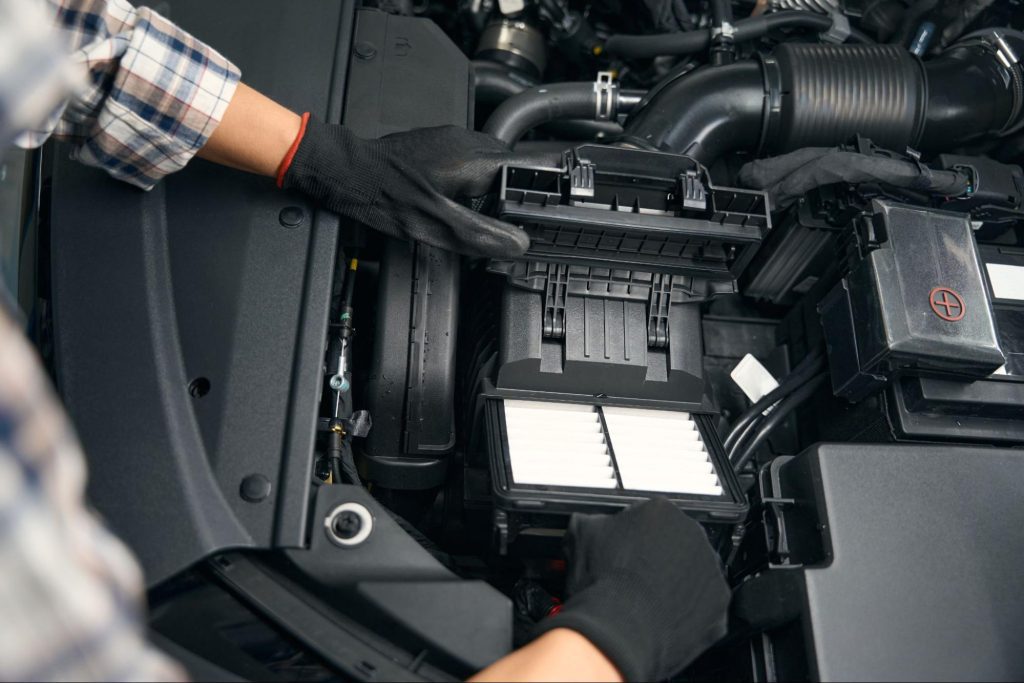

The Engine Control Module (ECM) Fuse is a crucial component within a vehicle’s fuse box that serves as a safeguard for the ECM, also known as the engine control unit (ECU). It is tasked with protecting the ECM from power surges or electrical failures, which can result from a variety of issues such as short circuits or overloads. The ECM itself is pivotal for many engine functions, including ignition timing, fuel injection, and emissions control.

If an ECM fuse blows, it can lead to several noticeable symptoms. These can range from engine stalling, rough idling, to loss of power. One might also observe the dreaded check engine light as the vehicle’s onboard diagnostics system registers error codes related to the electrical setback.

In modern vehicles, the ECM is connected to various sensors like the oxygen sensor, knock sensor, and ignition module which all rely on proper electrical flow. If the ECM fuse is blown, the functionality of these sensors, along with the fuel pump relay and ignition coil, can be compromised.

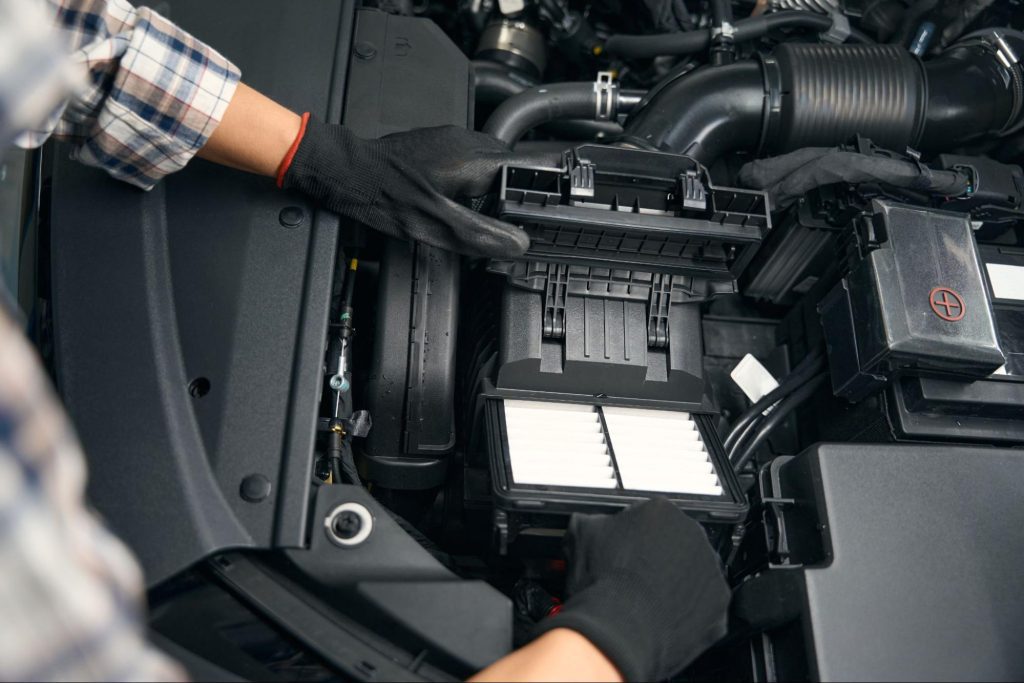

To protect the intricate systems of a vehicle, it is essential to check the fuse block located in the engine compartment periodically. A blown ECM fuse should be promptly replaced to maintain the integrity of the vehicle’s operation.

| Symptoms of ECM Fuse Issue | Possible Causes |

| Engine stalling | Short circuit |

| Rough idling | Electrical overload |

| Loss of power | Power surges |

| Check Engine Light | Faulty components |

How ECM Fuses Affect Engine Performance

The ECM fuse plays a vital role in safeguarding the Engine Control Module from electrical faults or power surges, which is essential for the module to regulate and control engine performance effectively. When an ECM fuse is functioning correctly, it ensures that the ECM can carry out its duties without interference, such as managing ignition timing and fuel delivery. On the other hand, a blown or malfunctioning ECM fuse can lead to a plethora of engine performance issues.

One of the key symptoms of a faulty ECM fuse is difficulties in starting the vehicle – the engine might crank but fail to ignite. If the ECM isn’t receiving power due to a blown fuse, it may not be able to control the fuel injector or ignition coil properly, leading to engine misfires. This disruption can cause a noticeable lack of power and hesitance during acceleration, as well as rough idling. More concerning is the potential for intermittent stalling, which can be particularly dangerous during high-speed driving or in heavy traffic.

Role in Communication with Sensors

The Engine Control Module is integral to the management and regulation of various sensor systems essential for optimal vehicle operation. One of its core functions is controlling the oxygen sensor, which is paramount in adjusting the air-fuel mixture to achieve efficient combustion. This seamless communication with the engine’s sensors is critical for maintaining vehicle performance. However, if the ECM fuse is blown, this communication is disrupted, leading to a plethora of issues. Symptoms such as difficulty starting the engine or encountering a rough idle may manifest when the ECM cannot relay information to and from the sensors effectively.

Troubleshooting these issues can be challenging due to the interconnectivity of the vehicle’s circuits. A professional diagnostic approach usually involves inspecting and verifying each circuit to isolate and remedy the fault. A blown ECM fuse can thus act as a significant barrier to the proper functioning of the vehicle, affecting the overall engine performance and potentially leading to stalls or decreased fuel efficiency.

Impact on Fuel Efficiency

One of the ECM’s essential tasks is the precise control of fuel injection, which prevents the wastage of fuel, thereby optimizing fuel consumption and improving overall efficiency. By continuously monitoring sensor inputs and adjusting the fuel delivery, the ECM ensures reliable engine performance, which is indispensable for maintaining consistent fuel efficiency under diverse driving conditions. A malfunctioning ECM due to a fuse issue may cause an improper fuel-air mixture, which can result in a marked increase in fuel consumption and a noticeable dip in fuel economy.

Moreover, the ECM has a direct impact on combusting efficiency by controlling the fuel-air mixture based on real-time sensor data, which also contributes to reduced emissions. Optimizing this combustion process leads to improved fuel economy and minimizes environmental impact. Conclusively, a properly functioning ECM, with its fuse intact, is essential for precise fuel delivery adjustments, ensuring peak engine performance and fuel efficiency while reducing unnecessary fuel expenditures.

Symptoms of a Blown ECM Fuse

When the ECM fuse in a vehicle blows, it can lead to a slew of symptoms that impact the vehicle’s operation and performance. One of the initial signs is engine stalling or misfiring. The ECM is responsible for orchestrating engine functions, and when its fuse fails, the overall synchronization of the engine’s workings is disturbed, which may lead to the engine unexpectedly stalling.

Difficulty starting the vehicle can also indicate a compromised ECM fuse. Since the ECM plays a crucial role in managing the engine’s ignition process, any deficiency in its power supply can prevent the ignition module and the engine from engaging properly.

Another troubling symptom of a blown ECM fuse is a noticeable loss of power, which manifests as sluggish acceleration and challenges in maintaining consistent speeds. The ECM’s inability to regulate the engine’s optimal operation due to a blown fuse directly translates to reduced engine output and performance.

Furthermore, the vehicle’s dashboard may flash warning lights, which are key indicators that something is amiss. Predominantly, the check engine light or the ECM/ECU malfunction indicator may light up, suggesting the need for an immediate checkup.

Lastly, other electrical components in the vehicle, such as the radio, power windows, or even the fuel pump relay, might be affected. This is a clear indication of broader electrical issues that may be traced back to a blown ECM fuse.

Engine Performance Issues

The health of the ECM fuse is directly tied to engine performance. It’s a vital link in the chain of electrical components that ensure the engine runs smoothly. If the ECM fuse has blown, it can result in poor fuel economy due to the ECM’s inability to precisely manage fuel injection and ignition timing. This inefficiency causes the engine to consume more fuel than necessary.

Rough idling is another byproduct of a faulty ECM fuse. With incorrect data or incomplete commands due to insufficient power supply, the engine struggles to maintain consistent RPMs at idle. Stalling can become a recurrent problem when the engine lacks proper management, leading to intermittent shutdowns that can occur without warning, even while driving—a situation that can be especially dangerous in traffic.

In some cases, the engine might still run, but with compromised ignition timing and fuel delivery, a drop in engine power is inevitable. This issue signals to the driver that the once seamless coordination between the engine control module and the engine itself is now disjointed, pointing again to possible ECM fuse troubles.

Warning Lights and Indicators

A blown ECM fuse is often communicated to the driver through warning lights and indicators. The most common among these is the check engine light. When the ECM fuse fails, the ECM itself cannot function correctly, triggering this light as a critical notification. Similarly, if the vehicle is equipped with an ECM/ECU malfunction indicator, this will also become illuminated as an alert.

The function of these warning lights is twofold: to inform the driver that there is a problem and to prompt an immediate response to avoid further damage or safety issues. While the check engine light can indicate various engine problems, if accompanied by any of the other symptoms mentioned earlier, it strongly suggests an ECM-related issue.

When these lights activate, it is generally advisable to seek professional diagnostic assistance. Ignoring these indicators can result in escalating problems that may ultimately compromise vehicle safety and engine longevity.

Electrical Malfunctions

Lastly, the ECM fuse safeguards the Engine Control Module against electrical malfunctions such as short circuits or power surges. When this fuse blows, it indicates an electrical anomaly within the vehicle’s system, and without protection, the ECM and associated components might suffer damage.

These malfunctions can originate from a variety of sources, including faulty sensors, wiring issues, or defective power relays. Diagnosing such problems often requires specialized equipment that can read and interpret the error codes stored in the vehicle’s computer system. These error codes provide clues about which component or circuit may be causing trouble.

In this context, the check engine light’s illumination acts as an early warning system. It’s a signal to investigate and address potential issues before they grow more severe. Electrical problems can affect an array of connected systems, from ignition coils and oxygen sensors to knock sensors and power accessories. Therefore, it’s paramount that any signs of electrical disruptions, particularly those surrounding the ECM, are taken seriously and inspected by a qualified technician.

Common Causes of ECM Fuse Failures

ECM fuse failures can be perplexing for vehicle owners. Modern vehicles have complex electrical systems, and the ECM fuse plays a pivotal role in protecting the Engine Control Module. When an ECM fuse blows, it can lead to a variety of engine issues, including stalling, loss of power, or even failure to start. Understanding the common causes behind ECM fuse failures is vital for troubleshooting and ensuring the smooth operation of a vehicle’s engine control systems and associated electrical components.

Overloading and Short Circuits

Short circuits, including the ECM fuse, are the primary threat to fuses within a vehicle’s fuse box. This perilous electrical event occurs when an unintended and low-resistance connection forms within the circuit, allowing an excessive amount of current to flow. This can rapidly generate a surge of power that the fuse is not rated to handle, resulting in a blown ECM fuse.

Common causes of short circuits leading to fuse failure include:

- Damaged wiring insulation exposing wires and leading to contact with metal surfaces

- Faulty or improperly installed electrical components that draw more current than the circuit is designed to provide

- Water intrusion into the electrical system, which can occur due to leaks, causes circuit pathways to short

Overloading of the circuit is another significant cause of ECM fuse issues. When devices or components draw more power than the circuit is designed to supply, it can cause an overcurrent situation. Overloading often occurs when too many devices or accessories are added to a circuit not rated for the additional load, potentially leading to ECM fuse failure.

Age and Wear of Fuses

Even without an immediate malfunction, such as a short circuit or overloaded circuit, fuses can fail due to the regular wear and tear of age. The metallic strip inside a fuse can corrode or oxidize over time, making it more fragile and susceptible to breaking even under normal operating conditions.

Factors contributing to the aging of fuses include:

- Constant exposure to high temperatures in the engine compartment can accelerate wear

- Frequent power fluctuations over the lifespan of the vehicle, stressing the fuse’s metallic filament

It is common for older vehicles to experience occasional fuse failures as part of normal wear and tear. Regular inspection of the fuse block can help identify and replace worn-out or aged fuses before they cause more significant issues.

Effective Diagnostics for ECM Fuse Problems

When it comes to diagnosing issues with the ECM fuse, a systematic approach is key. The ECM fuse is a crucial component that ensures the engine control module receives the necessary battery power. Faults here can lead to a variety of problems, such as engine stalling, incorrect ignition timing, and malfunction in various sensors like the oxygen sensor or knock sensor. To effectively troubleshoot, technicians need to understand the symptoms of a blown ECM fuse, which may include the illumination of the engine light, loss of power, stalling, and unexpected power surges.

Diagnosing ECM fuse problems can start with a visual inspection, but it often requires a more nuanced approach to reveal issues like intermittent fuse blows or those caused by underlying electrical problems. Error codes read through a vehicle’s OBD (On-Board Diagnostics) system can provide valuable insights into issues that may cause ECM fuses to fail. These codes help pinpoint specific issues, whether they’re within the ECM itself or related to the fuel injector, the ignition module, the fuel pump relay, or other connected components.

Ensuring Engine Reliability Through ECM Fuse Maintenance

The ECM fuse is a crucial component safeguarding the Engine Control Module—a brain for modern vehicles—against power surges and shorts. It’s usually located in the engine compartment, within the fuse box or fuse block. A blown ECM fuse can lead to several issues such as engine stalling, rough idling, and loss of power. It may also trigger the check engine light and store error codes. Identifying a blown ECM fuse involves inspecting the fuse box for any damaged fuses and using a multimeter to check for continuity.

Recommendations:

- Regular Checks: Periodically inspect the ECM fuse as part of routine vehicle maintenance.

- Symptom Awareness: Be vigilant of symptoms such as engine light alerts, engine stalling, and power inconsistencies.

- Professional Diagnosis: If a blown fuse is suspected, a qualified technician should diagnose the issue, as it could be indicative of larger electrical problems.

- OEM Replacements: Always use manufacturer-recommended fuses to replace a blown ECM fuse.

- Address Underlying Causes: Simply replacing a blown fuse may not be enough; identify and rectify the root cause to prevent future occurrences.

Having an understanding of the ECM fuse and addressing issues promptly ensures that essential engine functions and related components, such as the fuel pump, ignition module, and various sensors, operate reliably.

Enhance Your Vehicle’s Performance: Reflashing and upgrading your vehicle’s control modules can significantly improve performance. Learn more about our services at SoloPCMS.com and see how we can help your vehicle run smoothly and efficiently.