Dodge PCM & Engine Computer Programming

The Dodge Powertrain Control Module (PCM) vehicular computer engine control system installed in models produced between 1993 to 2003, supplied microprocessor control support to machine functions and interoperating across all onboard systems.

While newer vehicles come with standard applications ready for owner use, older automobiles with PCM modules require code sourcing.

Where to Find Programming Instructions?

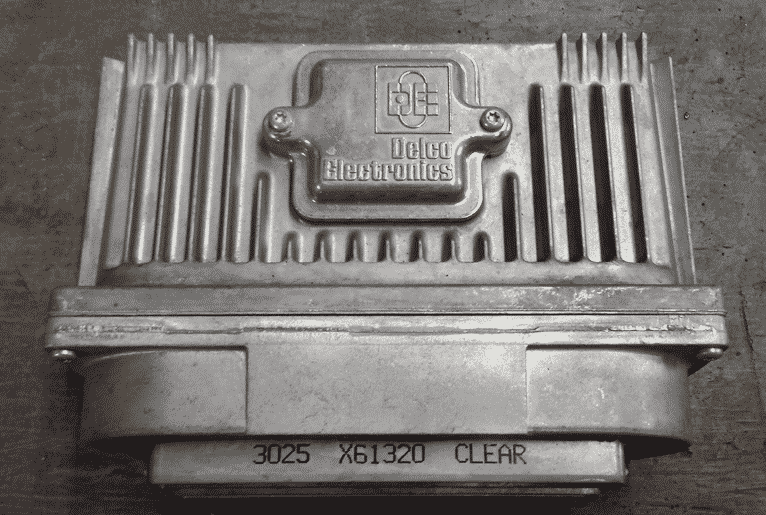

PCM module identification for programming is found in the calibration chip and PROM.

Programming instructions for vehicle systems applications are stored on flash memory or the PCM Electronically Erasable Program Read Only Memory (EEPROM).

If replacement is required, reprogramming of the PROM can be done once installed.

Dodge PCM Flash Programming Code

Updates to PCM flash programming code are available through the manufacturer.

PCMs in good working order can be accessed for reprogramming via the EEPROM chip without removal of the vehicular computer engine control system.

Consumer applications now make it possible for owners of newer Dodge vehicles to diagnose and reprogram PCM according to manufacturer specifications.

Mobile diagnosis is now possible, so that the proper access codes and input data can be obtained on the road.

Identification of PCM programming code requires knowledge of vehicle year, model and engine size, as well as OEM part number of the PCM unit.

Reprogramming of PCM is not common aftermarket. Reprogramming may alter engine performance and catalytic functions.

Transmission modules must be reset with factory DRB scanner tools, supplied with dealer codes to accurately set pinion factor operations to the speedometer.

PCM Programming During Remanufacture

Remanufactured PCM units are less expensive but inevitably run into programming issue if not rehabilitated by a certified source.

Powertrain control modules are expensive to remanufacture for this reason. Testing of the PCM is required during remanufacturing to ensure that the control module is functioning properly.

The remanufacture process follows diagnostic audit of the PCM.

Isolation and repair of faults located in the powertrain control module should be met with subsequent testing for assurance that the vehicular computer engine control system is working properly, and that interoperability once installed is fully functioning.

The integrated infrastructure of sensors and mechanics should automatically synchronize interoperability features with driver behavior.

For a free consulting about all related to PCMs, contact us!